SnowBlowers are an important piece of equipment that improves your convenience, especially during the winters. If you have tried to start your snowblower with the three pulls of the starter rope without success, then here are some effective tips that would help you to turn the equipment back up and running.

One of the most common causes behind snowblower issues is the lack of maintenance. Ensure that you maintain the equipment properly throughout the year so that it can operate efficiently when required.

You would need to Identify the problem associated with the equipment at first. There can be issues with fuel level, spark plug, carburetor, or compressor. Depending on the type of problem your snowblower is facing, the troubleshooting steps would vary. We would explain it all in this article.

Troubleshooting the snowblower starting issues

All snowblowers generally consist of the same parts- valves, carburetors, fuel lines, etc., but their location and certain features might vary a bit depending on the brand. Thus, it is important to keep its manual handy. Once you have that, take up the required tools from auto-shops and be ready to troubleshoot the equipment.

Step 1 – Check all the switches and valves

You would need to ensure that all the switches and valves of the equipment are in the right starting position. Different brands have different types of switches located on various areas of the equipment. You should make sure that each of those should be in the “ON” position, which is extremely important.

You can read the manual given by the manufacturer to see if all the switches and valves are in the right position. Sometimes, the issues are as simple as turning a switch on and we conduct complex troubleshooting steps which are not at all required.

Step 2 – Replace the old gasoline

Now that you have checked all the switches and valves, it is the time to replace your old gas. Your machine has been sitting idle since the last few months and hence it is susceptible to developing gummy residues. Use a siphon pump to take out the old gasoline and then fill the tank with fresh gas. You can then try and see if the snowblowers start.

Step 3 – Remove the residue

If the snowblower is not starting still, chances are there that the gummy residues have filled up in the gas line causing a blockage in the carburetor. You can dissolve this by adding fuel stabilizer that basically liquifies the residues.

You should put the required amount of stabilizer, as suggested on the container and then start the machine up. Try and pull the cord several times in case the machine does not start up immediately. If it’s still not working, wait for a few hours for the stabilizer to work and then try starting the equipment up.

Step 4 – Press the primer bulb

Now, it is the time to prime the engine so that it can create a force on the fuel to go into the carburetor smoothly. These equipment work intermittently during the winters, and this prime boost would give the machine that energy to work properly.

You should start by pressing the flexible primer bulb for three to five times, and once done try to start the snowblower immediately. You might have to do multiple attempts to start the machine up, since it has been sitting idle for so many days.

Step 5 – Clean the spark plug

Having a clean spark is another important element that your snowblower would need to start up. The spark basically helps the fuel to ignite and hence it is vital that this piece of equipment works properly. You can first clean the spark plug and then can replace it, if necessary. Make sure to get a new one if you find a crack in the spark plug.

Step 6 – Check the fuel line

You should also check the fuel line to see if it’s flexible and pliable. During cold weather conditions, they are susceptible to getting hard and tend to get brittle. You should also check for cracks, in and around the connectors. In case you witness leak, crack, or any other issues with the hard line, it’s time to change it.

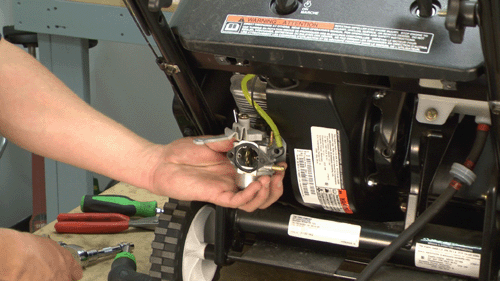

Step 7 – Clean the carburetor

If none of the above steps work, this might be the time to clean the carburetor. The residue might create a blockage inside this machine part, causing a blockage. It would prevent the fuel from combusting. You can refer to the manual to understand where the carburetor is located and how you can effectively clean it. You can use solvents to get better results.

Conclusion

These are some of the effective steps that you can perform to start your carburetor. Follow the user manual to perform these steps efficiently. If none of these works, it is time that you should call a professional technician to look after the matter. Delayed servicing might cause more harm to the machine, and you might have to end up spending more.

Jan 8, 2024

Jan 8, 2024  Jan 8, 2024

Jan 8, 2024  Jan 8, 2024

Jan 8, 2024  Jan 8, 2024

Jan 8, 2024  Jan 8, 2024

Jan 8, 2024