People sometimes use the words “self-drilling” and “self-tapping” interchangeably, but two entirely separate types of screws are actually identified.

In certain areas, it is important to consider the distinctions between self-drilling and self-tapping screws to better execute building tasks.

Using the wrong fastener form can lead to weakened joints among materials and a greater risk of catastrophic failure.

Screws that have especially sharp threads that can carve through the material are often alluded to as “self-drilling screws.” But, when dealing with these types of screws, there is a differentiation worth considering, which can make a huge difference between their usage and use.

The screws are typically divided into two main categories that are known as “self-drilling” or “self-tapping” and are not compatible in these ways. Technically, each of these screw types can tap their own threads, however, the self-drilling screws are special (as most screws do to a certain degree).

Want To Share This On Your Site? Just Copy The Below Code!

What is a Self-drilling screw?

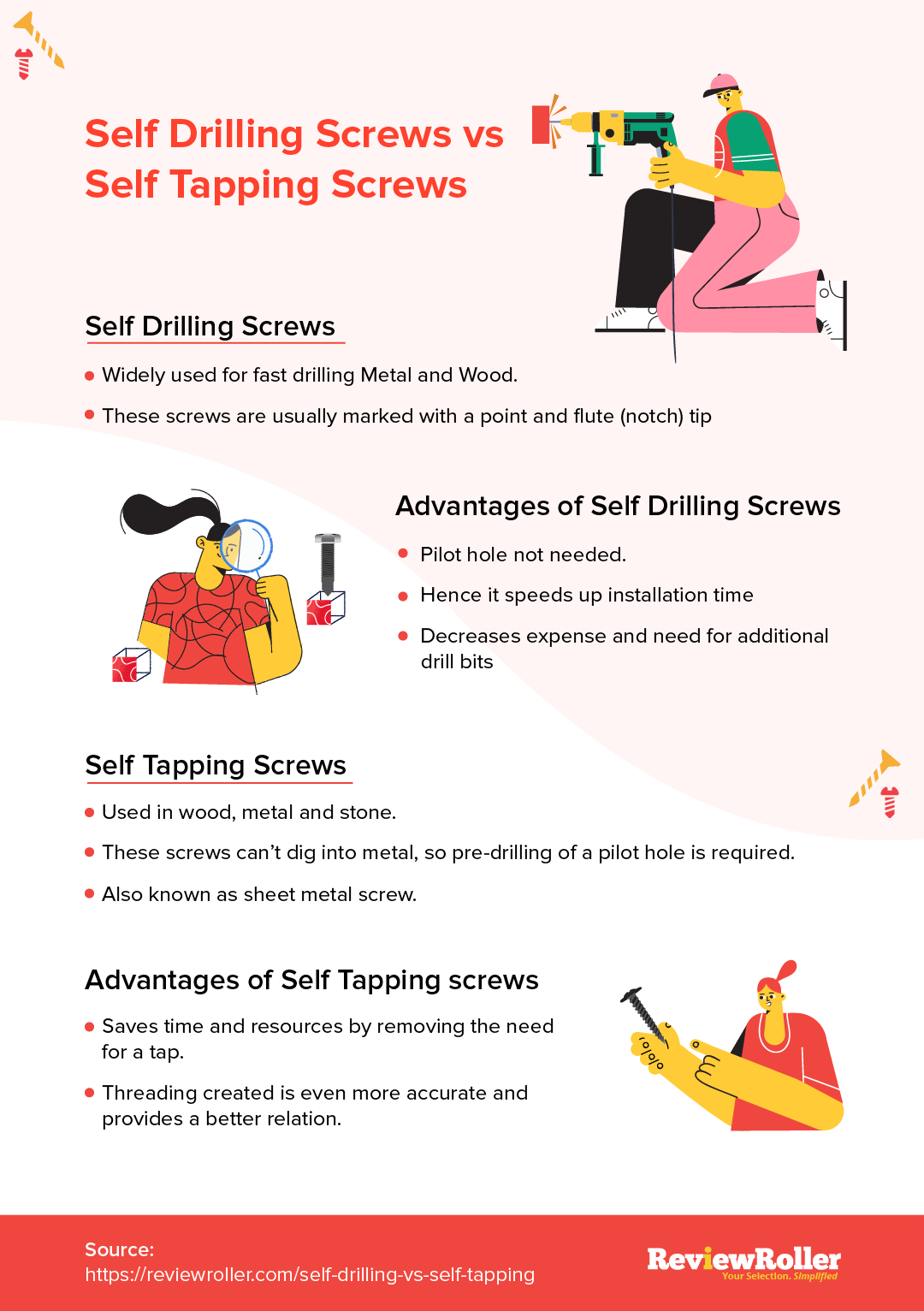

Self-drilling screws are a widely used variation of screws for fast drilling in both metal and wood. Usually, a self-drilling screw may be marked with a point and a flute (notch) tip. This tip functions as a screw drill bit, making it much easier to install than to turn between the drill bit and the drive bit.

These are invariably made of sturdy steel or other metal that has been treated to improve its hardness (such as 410 stainless steel). Often make sure that the steel you drill into is smoother than the screw material itself by using self-drilling screws. Otherwise, the tip of the drilling screws would be rusty and not dig into the material.

Often, self-drilling screws are recognized by the branded version, Tek ® Screws. The drill bit-shaped tip of the screw may classify these screws which are designed for a range of applications, such as two dissimilar metals and metal to wood fastening.

A pilot hole is not needed for self-drilling screws, which speeds up the installation time and decreases the expense and need for additional drill bits.

Self-drilling screws are the simple choice for metal construction projects with this added flexibility and cost-saving capability.

What are the benefits of using a Self-drilling screw?

Self-drilling screws are easy to deduce when you look at their end, which bends softly at the edge and is formed like a twist drill. They are also called Tek Screws, just after the brand that popularized them.

These screws can connect metal to metal, wood to alloys, and work well with light, reduced-density materials. In particular, they have more advanced uses than self-adhesive screws. They’re fantastic for metal fabrication and metal light gauge assembly.

To receive wood chips or metal filings, the notched region at the tip serves as a reservoir. This provides the space needed for the screw to drill/screw all the way into place.

Self-drilling screws are a money saver that prevents both (in most cases) the drilling measures and the tapping of a cavity before installation. Also, it reduces the need for each gap for drill bits or taps and flipping between them.

Self-drilling screws require no pilot hole to cut and attach, unlike self-tapping screws; they can dig, tap, then fasten with one go, which prevents you from the extra phase of drilling, then attaching.

What is a Self-tapping Screw?

Self-tapping screws remove the need for a tap by providing sharp cutting threads that can tap the thread themselves when being fastened. There are two big advantages to the use of self-tapping screws. First, they save time and resources by removing the need for a tap.

The second is that the resulting threading they create is even more accurate and provides a better relation. Self-tap screws are made of steel and masonry materials which have been widely used, but there are also alternatives which can be cut into plastic or timber.

For all kinds of materials, including wood, metal, and stone, self-tapping screws are used. These screws are not able to dig into metal and require the pre-drilling of a pilot hole before deployment.

By using a drill bit that is slightly smaller than the screw, a pilot hole is formed and the threads of the screw tap the metal or wood as the screw is being mounted. The substance is fastened together by this tapping motion. A self-tapping screw may have various levels that aid in tapping threads onto various surfaces.

Also, before the fastening process is initiated, a self-tapping screw usually involves an initial pilot hole. It is important to note the material’s hardness and strength when selecting the correct form of a screw.

What are the benefits of using a Self-tapping screw?

A self-tapping screw may be defined specifically simply as a tapping screw but is often commonly referred to as a sheet metal screw because it is used so extensively in the trade-in sheet metal. To cut through the material and produce its own connectors, Self-Tapping Screws have cutting tool threads.

Whatever term is used, a self-tapping screw (or sheet metal screw) is designated as that because it includes form-matting threads (thus “tapping” threads) throughout the pre-drilled hole through which they are pushed.

The most notable distinction between self-tapping and self-drilling screws is that without a pilot hole, that must be pre-drilled or post-punched, self-tapping screws will not go through steel.

Also critical is the exact drill or punch hole size. If the hole’s too wide, the screw may get loose and not thread correctly and safely. The screw will snap or cause the material to split or crack if the hole is too wide.

What is the difference between a self-drilling screw and a self-tapping screw?

Both self-drilling screws are self-tapping by the essence of how they function. A self-drilling screw is a type of self-tapping screw that often includes a drill point. The blunt drill point would both make a hole and shape the joining threads in one process.

Between these two self-drilling screws, though, there are two significant benefits: time and costs of living at assembly time and decreased mounting error, which also occurs as one pre-drill hole throughout the wrong size.

In the world of fasteners, the normal solution that is safer comes almost exclusively to the case that the fastener is used for. From a time-saving viewpoint, a self-drilling screw is a perfect option because it can remove the need for a drill bit and make the assembly a one-step operation. They all have their location, though, and it comes down to choosing who to choose in the problem at hand.

Two types of screws used in metal fabrication and building services, as well as many other uses and fields, are self-tapping and self-drilling screws. The two words are not synonymous, contrary to popular opinion.

In short, all self-drilling screws are self-tapping screws as well, and this is where the misunderstanding lies, but all self-tappers really aren’t self-drillers. Self-drilling screws remove, but can also tap, the need for a hole.

Self-tapping screws tap their many threads, but need a pilot hole and cannot punch into metal. Such screws are not identical and often headaches or potential faults in the field can be caused by mixing the two.

Along with their ability to build a perfect match, self-tapping and self-drilling screws are the fasteners of choice for manufacturing, HVAC, and other industries. They can be used for brass, aluminum, wood, drywall, and plastic fastening. For thin sheet metal (one or second layer) and masonry applications, self-tapping screws are also appropriate.

In a large range of sizes, these screws are accessible. When fastening a self-tapping or self-drilling screw, depending on the screw size, manufacturers also prescribe applied force and drive motor speeds.

Conclusion

In essence, a self-drilling screw is indeed a self-tapping screw with both the drill point function attached. With any form, for a close match, the screws carve mated threaded into the substrate.

Usually, all kinds of screws are made of heavy steel or stainless steel that has been treated to improve its hardness. To avoid the collapse of the joint or disruption to the pin, material, or fastening tool, the screw must be thicker and more robust than the material it would drill through.

A self-tapping screw may also be self-drilling, which is where the misunderstanding stems from. Basically, a self-drilling screw is a tapping screw that doesn’t require a pilot hole. Essentially, they each tap their own strings, and both screws do this to different degrees. But, a step in the process is skipped by the self-drilling screws.

They are suitable for connecting thin sheet metal to metal or wood frames because of the way self-drilling screws are made. Self-tapping screws are suitable for metal with a drill bit, they are also sometimes variously referred to as threaded inserts

Jan 8, 2024

Jan 8, 2024  Jan 8, 2024

Jan 8, 2024  Jan 8, 2024

Jan 8, 2024  Jan 8, 2024

Jan 8, 2024  Jan 8, 2024

Jan 8, 2024